Types of Industrial Retractable Safety Barriers Explained: A Guide to Choosing the Right Warehouse and Factory Solutions

15th Jan 2026

Industrial retractable safety barriers are portable or fixed systems that deploy a retractable belt or expandable barrier to control access, segregate pedestrians from vehicles, and cordon temporary hazards in warehouses and factories. They work by creating a clear visual and physical boundary—using posts, wall-mounted housings or concertina frameworks—so staff and plant operators can manage routes, protect work zones and reduce collision risk. Choosing the correct type improves operational flow, reduces downtime from incidents and helps meet recognised safety expectations such as PAS 13 and HSE/PUWER guidance. This guide defines the main barrier types, explains how wall-mounted and expandable systems function in constrained industrial environments, maps common pedestrian and vehicle safety applications, and provides a practical features checklist to aid procurement decisions for warehouse safety barrier solutions.

What Are the Main Types of Industrial Retractable Safety Barriers?

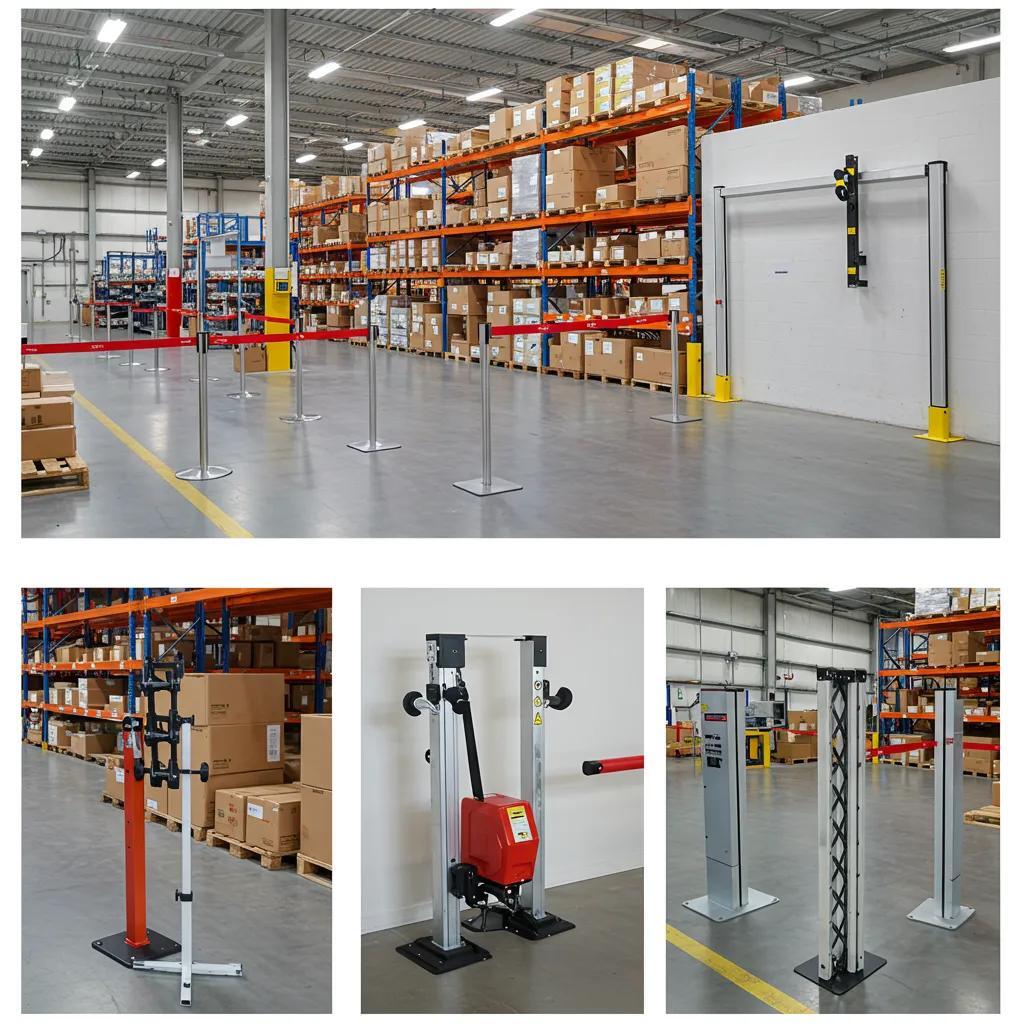

Industrial settings typically rely on three core retractable barrier families that balance portability, permanence and closure strength for different tasks. Each type addresses distinct operational needs: freestanding retractable belt barriers for rapid temporary cordons, wall-mounted retractable barriers for space-saving closures, and expandable (concertina) barriers for longer, heavy-duty temporary separations. Understanding these hyponyms within the broader category of industrial safety equipment helps match barrier choice to hazards such as spill response, aisle closure and loading bay isolation.

Common industrial retractable barrier types include:

- Freestanding retractable belt barriers: Portable posts with a retractable belt used to cordon spills or redirect pedestrians quickly.

- Wall mounted retractable barriers: Fixed housings with a deployable belt ideal for narrow corridors and doorways where floor space is limited.

- Expandable (concertina) safety barriers: Telescoping metal or polymer gates suited to longer closures and heavier-duty exclusion zones.

These primary categories highlight the trade-offs between flexibility, permanence and strength; the following table summarises materials, form and typical applications for quick procurement reference.

The following quick-comparison table clarifies typical construction and use-cases for each barrier family.

|

Type |

Typical material & form |

Typical application / benefit |

|---|---|---|

|

Freestanding retractable belt barriers |

Steel or polymer post with weighted base and fabric/polymer belt |

Rapid temporary cordons, queue control, spill isolation |

|

Wall-mounted retractable barriers |

Metal bracket and cassette with polymer belt |

Space-saving door/corridor closures, consistent placement |

|

Expandable (concertina) safety barriers |

Steel or reinforced polymer accordion frame |

Long temporary closures, loading bay or machine exclusion |

This comparison makes it easier to shortlist options by application and environment before reviewing specific features and installation needs.

What Are Retractable Belt Barriers and Their Industrial Uses?

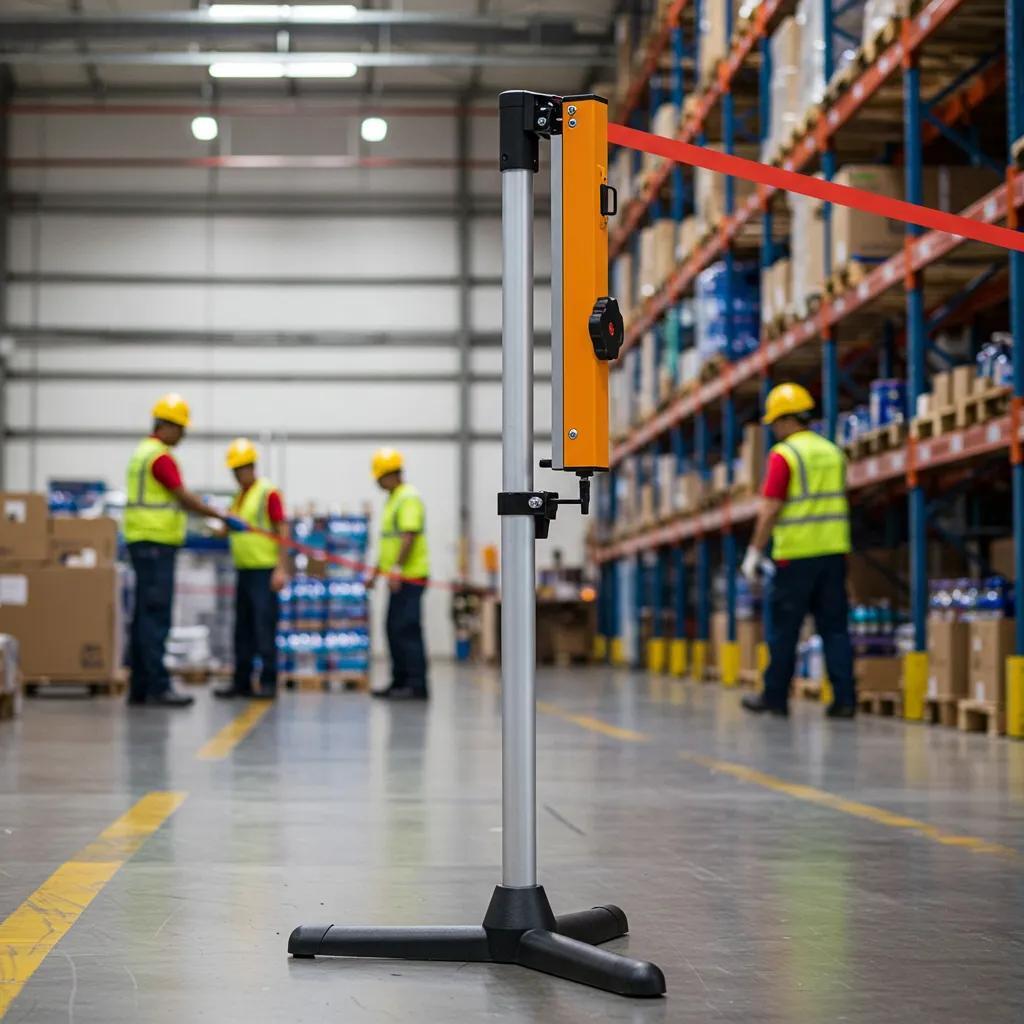

Retractable belt barriers combine a vertical post, a retractable belt mechanism and a base to form a rapid, re-deployable cordon that controls access and guides movement. The mechanism stores the belt inside the post cassette and releases it to clip into receivers on neighbouring posts or wall fittings, allowing flexible configurations for aisles, shift-change queues and spill zones. In warehouses they are commonly used to segregate pedestrian walkways from forklift corridors or to temporarily close an aisle for maintenance; belt length, base stability and connection options are critical specs to check.

Understanding indoor versus outdoor suitability—polymer belts and weighted bases for indoor use, corrosion-resistant finishes for external exposure—helps match a freestanding belt solution to the task at hand.

How Do Expandable Safety Barriers Work in Factories?

Expandable or concertina safety barriers deploy by extending an accordion-style frame that locks into position to create a continuous physical barrier without multiple posts. These units are typically manufactured from metal or reinforced polymers to balance portability with higher lateral strength compared with simple belts, making them suitable where a longer continuous closure is needed or ground anchors may be applied. Expandable barriers are useful for isolating large maintenance areas, creating temporary lane closures in loading yards and providing a visible, sturdy separation between vehicle routes and pedestrian access. When choosing an expandable gate, consider frame stiffness, locking mechanisms and storage footprint to ensure it meets the required duty cycle.

How Do Wall Mounted Retractable Barriers Improve Industrial Safety?

Wall-mounted retractable barriers provide a compact, permanently available closure point that deploys a belt across openings without consuming floor space or requiring stanchions. Because the cassette is fixed to a robust bracket, deployment is immediate and repeatable—ideal for narrow corridors, doorways to plant rooms and stairwell control—so they reduce trip hazards caused by loose posts and maintain consistent barrier placement. Installation considerations include bracket fixing to structural surfaces, cassette orientation for left/right deployment and material choice to resist corrosion in washdown or outdoor-exposed locations. The following list highlights the principal operational benefits to help specify wall-mounted solutions in constrained industrial layouts.

Wall-mounted barriers deliver three main operational advantages:

1. Space saving: They free floor space by eliminating freestanding posts in narrow aisles and doorways.

2. Immediate availability: A permanently mounted cassette provides fast, reliable closure during incidents or shifts.

3. Reduced obstruction: Fixed mounting lowers the chance of trip-related incidents compared with loose posts.

These benefits make wall-mounted retractable barriers a strong choice where permanent or semi-permanent access control is needed without compromising aisle capacity.

What Are the Benefits of Wall Mounted Barriers in Limited Spaces?

In tight industrial footprints, wall-mounted retractable barriers secure openings without introducing a base or post that could obstruct pedestrian or equipment movement. Their compact cassettes sit on the wall at a controlled belt height, meaning closures are consistent and do not rely on deploying multiple components during an emergency or maintenance activity. This predictability reduces human error during rapid deployment and lowers the likelihood of trips or misplaced stanchions blocking forklift access. For environments where cleanliness and clear walkways are priorities—such as food-handling zones or narrow stairwell approaches—wall-mounted systems improve both safety and operational flow.

Which Materials Are Used for Durable Wall Mounted Barriers?

Durable wall-mounted barriers typically pair a metal bracket and cassette with a polymer or woven belt; stainless steel components and impact-resistant polymers are common where corrosion or impact exposure is anticipated. Stainless steel offers excellent corrosion resistance for outdoor or washdown environments, while engineered polymers provide impact absorption and reduced weight for less demanding indoor locations. When specifying material, consider surface finish, UV stability for outdoor belts, and cassette sealing to prevent ingress in dusty warehouse settings. Prioritising the right materials increases lifespan and reduces maintenance, which supports both safety and total cost of ownership.

How Do Industrial Retractable Barriers Enhance Pedestrian and Vehicle Safety?

Retractable barriers create clear, temporary physical boundaries that channel foot traffic, prevent unauthorised access and signal hazard zones to vehicle operators, thereby reducing the risk of collisions and near-miss incidents. By combining high-visibility belts, reflective patterns and strategic placement, barriers clarify routes for pedestrians and define exclusion areas for forklifts and delivery vehicles.

They are effective for creating safe pedestrian walkways, isolating loading bays during operations and providing rapid cordons during spill response or equipment breakdown. The next subsections explain common pedestrian deployments and the role barriers play in managing vehicle traffic and hazard zones.

Common use-cases where barriers improve safety include:

- Pedestrian segregation: Creating protected walkways alongside busy forklift routes.

- Loading bay control: Temporarily closing dock edges during unloading or when fall protection is required.

- Hazard cordons: Rapidly isolating spill or maintenance zones to prevent staff exposure.

These applications demonstrate how barriers link behavioural cues with physical separation to reduce incident rates.

How Are Retractable Barriers Used for Pedestrian Safety in Industrial Settings?

For pedestrian safety, retractable barriers are typically conpd to form continuous walkways, guide queues at shift changes or cordon off temporary hazards while maintaining visibility and access for emergency egress. Effective deployments use high-contrast belt colours, appropriate belt height and clear connection patterns that leave unobstructed escape routes; belts should not create trip hazards or impede evacuation. Practical setup tips include placing barriers to enforce single-direction flow where needed, using wall-mounted units in narrow corridors and combining posts with anchor points for long runs. These measures help ensure pedestrian segregation is robust, visible and compliant with principles in PAS 13 and HSE guidance.

What Role Do Barriers Play in Vehicle Traffic and Hazard Zone Control?

In vehicle areas, barriers delineate vehicle routes, protect loading operations and create temporary exclusion zones that prevent accidental incursions by trucks and forklifts. High-visibility belts, reflective elements and solid expandable gates increase detection by vehicle drivers, while durable posts and weighted bases resist incidental contact. When used alongside traffic management controls—such as floor markings and signage—barriers form part of an engineered approach to reduce collision risk in busy yards and internal transport routes. Choosing materials and visibility features suited to vehicle exposure is essential to maintain barrier effectiveness and longevity.

What Features Should You Look for in Industrial Retractable Safety Barriers?

Selecting the right barrier requires a checklist of technical and practical features that align with industrial demands: build durability, belt visibility and messaging, belt length and connectivity, base stability, and supplier logistics like dispatch and customisation. Durable construction (stainless steel or impact-resistant polymer), long belt reach for wide aisles, and clear visibility options (high-contrast colours and reflective strips) directly influence on-site performance and compliance. Procurement should also consider supplier value propositions such as rapid dispatch to meet urgent needs, price guarantees to control cost, and customisation for belt messaging to communicate site-specific hazards. The table below organises these selection attributes to help purchasers compare specifications.

The following table helps translate key features into practical specification checks.

|

Feature |

Why it matters |

What to look for in specs |

|---|---|---|

|

Durability & material |

Determines lifespan and exposure suitability |

Stainless finishes, UV-stable belts, impact-resistant polymer |

|

Belt length & connectivity |

Affects coverage and configuration flexibility |

Maximum retractable length, receiver types, multi-connect options |

|

Visibility & customisation |

Improves hazard communication and compliance |

High-contrast colours, reflective strips, belt messaging options |

|

Base stability & mounting |

Ensures stability under contact or vehicle proximity |

Weighted or flanged bases, wall-bracket strength, anchor points |

This checklist frames technical requirements into actionable spec items buyers can request from suppliers.

How Do Durability and Material Choice Affect Barrier Performance?

Material selection affects corrosion resistance, impact absorption and maintenance frequency, all of which influence total cost of ownership and operational reliability in industrial settings. Stainless steel posts and brackets deliver structural robustness and long-term corrosion resistance for outdoor or washdown zones, while engineered polymers absorb low-energy impacts and reduce repair costs for internal use. Consider whether a barrier will frequently interact with vehicles—if so, prioritise stiffer frames and replaceable components; for chemical or moisture exposure, select stainless or sealed polymer cassettes. Matching material properties to the intended duty cycle minimises unscheduled downtime and supports continuous safety performance.

What Customisation and Visibility Options Are Available for Safety Barriers?

Modern retractable barriers offer belt colour choices, reflective patterns and printed belt messaging that communicate hazards, permit zones or temporary instructions to staff and operators. Customised belt messaging can state specific cautions or directional information and is particularly valuable in multi-language sites or areas with changing risks; reflective elements improve detection in low-light vehicle areas. When specifying customisation, confirm print durability, colourfastness and whether the supplier can deliver bespoke messaging as part of the order. Integrating visibility and messaging into barrier selection enhances compliance with site rules and ensures barriers do more than just block access—they actively communicate risk.

Retail Display Direct supplies a range of relevant product categories such as Retractable Barriers and Posts and Wall Mounted Retractable Barriers, which can be useful when sourcing solutions that meet these feature criteria. Their supplier advantages—same day dispatch on most orders before 11am, a lowest-price guarantee, durable indoor/outdoor options and belt customisation—translate directly into procurement benefits for urgent or bespoke industrial deployments.

For immediate procurement needs, consider those product categories and request quotations that specify material finishes, belt lengths, and custom messaging so your chosen barriers align with PAS 13 and site-specific hazard controls.