How Portable Retractable Safety Barriers Enhance Workplace Safety

12th Jan 2026

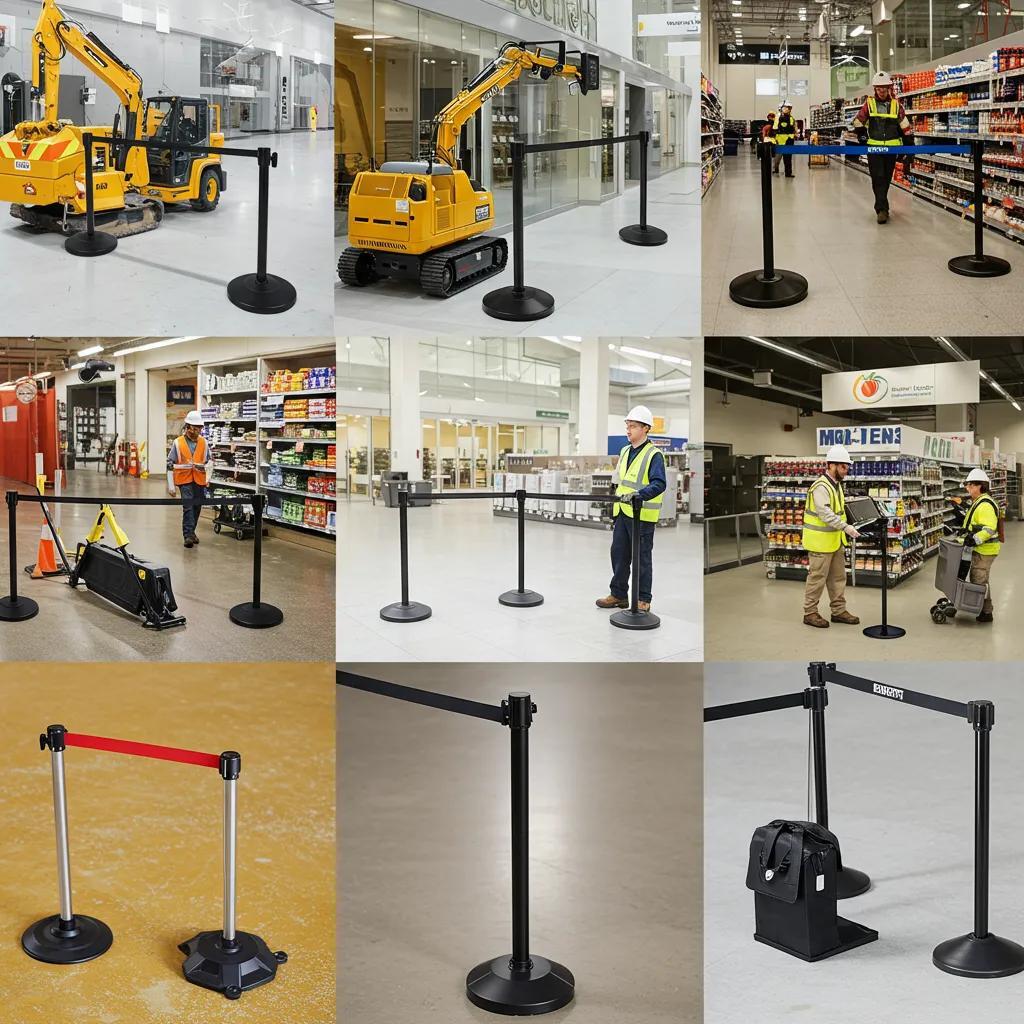

Portable retractable safety barriers are freestanding systems that use wound belts, expandable sections or stanchion posts to create temporary exclusion zones and guide pedestrian flow. They work by providing a visual and physical deterrent that defines hazard areas, reduces unauthorised access and channels movement away from risk, improving situational awareness in busy workplaces. This article explains how these temporary barriers improve hazard demarcation and visibility, why rapid deployment matters for reducing exposure time, which industries gain the most safety benefit, and how barriers map to UK compliance frameworks such as PAS 13 and PUWER. Readers will find practical selection guidance on material, base and visibility options, quick-reference comparison tables, and short checklists for deployment and inspection. Throughout the piece we use terms like portable retractable safety barriers, retractable belt barriers and safety stanchions to ensure technical clarity and to show how choices align with real-world applications. By the end you should be able to match barrier attributes to common workplace hazards and pick options that keep staff and visitors safer while remaining operationally efficient.

What Are the Main Benefits of Portable Retractable Safety Barriers?

Portable retractable safety barriers deliver clear visual cues, rapid segregation of hazards and flexible access control, helping organisations reduce exposure to dynamic risks. They combine high-visibility belts or ropes with modular posts or expandable frames so that temporary danger zones—such as wet floors, maintenance areas or vehicle access points—are immediately obvious and physically discouraged. The primary value is reducing incident probability through clearer demarcation, faster response, and reusability that lowers lifecycle cost versus ad-hoc tape or improvised barriers. Below is a concise comparison of common barrier types to help choose the right approach for a given setting.

Portable barrier comparison by key attributes:

|

Barrier Type |

Portability |

Visibility |

Deployment Speed |

|---|---|---|---|

|

Retractable belt barriers |

High (freestanding posts) |

High (contrasting belts) |

Seconds per post |

|

Expandable safety barriers |

Medium (folding frames) |

Medium (solid panels) |

Under a minute |

|

Rope barriers / stanchions |

High (lightweight posts) |

Medium (rope visibility) |

Seconds per post |

This table highlights how retractable belt barriers excel where rapid, high-visibility demarcation is required, while expandable barriers suit longer temporary closures. For practical purchases, suppliers such as Retail Display Direct offer portable retractable safety barriers, retractable belt barriers and rope barriers designed for easy transport and versatile use; these product categories typically emphasise durability, portability and fast deployment to match the benefits described.

How Do Retractable Barriers Improve Hazard Demarcation and Visibility?

Retractable barriers enhance hazard demarcation by combining contrast-coloured belts or tapes with consistent post height, which creates an immediately recognisable perimeter around a hazard. The mechanism is simple: visual contrast plus a physical line reduces ambiguity about safe zones and channels behaviour away from danger, which is particularly effective in busy corridors, wet-floor incidents and temporary maintenance activities. Recent HSE guidance underscores that clear segregation is central to reducing slips, trips and collisions, and high-visibility belts or reflective options amplify that effect in low light or high-traffic areas. A quick visibility check for any barrier should include belt colour contrast, reflective striping where needed, and consistent post spacing to ensure the demarcation reads clearly from common approach angles.

These visibility improvements naturally lead to the next operational advantage: the speed and ease of deploying these systems in response to emerging risks.

Warning Barriers: Improving Safety in Industrial Workplaces

Warning barriers are essential safety devices in industrial environments, such as wood sawmills, used to delineate hazardous areas and communicate risks. They identify potential hazards, their associated consequences, and the requisite precautions to ensure worker safety and enhance working conditions. Work Safety and Safety Devices in Brazilian Wood Sawmills for the Improvement of Working Conditions, MFF Silva

Why Are Portability and Quick Deployment Crucial for Workplace Safety?

Portability and quick deployment matter because many workplace hazards are transient—spills, short-term maintenance, equipment testing—and each minute of uncontrolled exposure increases the chance of injury. Portable retractable barriers fold, retract or click together to create a controlled perimeter within seconds, significantly reducing the time a hazard is accessible. In addition to rapid response, the storage footprint and transportability mean teams can carry barriers to the point of need without specialised vehicles or lifting equipment. Best practice is to store a small fleet of mobile barriers near high-risk areas so that response is immediate; this operational readiness reduces downtime and maintains safe workflows while permanent solutions are planned.

Crashworthiness Assessment of a Deployable Work-Zone Barrier

This portable maintenance work-zone barrier was developed for rapid, straightforward, and safe deployment at the worksite. Although no specific testing criteria exist for this barrier type, it underwent testing according to NCHRP guidelines to evaluate its crashworthiness and efficacy in establishing a secure working environment. Crashworthiness testing of a portable maintenance work-zone barrier., 2008

Which Industries Benefit Most from Portable Retractable Safety Barriers?

Portable retractable safety barriers are valuable across a wide range of sectors because they address transient hazards, pedestrian-traffic separation and temporary access control without permanent installation. Industries that benefit most include construction, industrial warehouses, retail environments and events management, as each of these settings experiences dynamic flows of people and equipment where quick segmentation prevents incidents. Barriers can be matched to the environment—for example, heavy-duty bases and robust posts for uneven outdoor sites, or sleek stanchions and branded belts for retail queuing—so that the safety solution is both functional and appropriate to the context.

Industry-to-recommendation mapping:

|

Industry |

Primary Safety Need |

Recommended Barrier Type/Feature |

|---|---|---|

|

Construction / Industrial |

Exclusion zones, rough ground stability |

Expandable frames or weighted-base retractables |

|

Warehouses |

Pedestrian segregation from forklifts |

Retractable belt barriers with high-visibility belts |

|

Retail |

Queue management and temporary closures |

Decorative stanchions, branded belts |

|

Events / Public spaces |

Crowd flow and temporary rerouting |

Lightweight retractable posts, multiple connector options |

This mapping shows that warehouses and construction sites typically need rugged bases and high-visibility belts to withstand traffic and uneven surfaces, while retail and events can prioritise appearance and rapid reconfiguration. Retail Display Direct’s product categories—portable retractable safety barriers, retractable belt barriers and rope barriers—fit these needs by offering variants tuned to durability, portability and visual prominence.

How Do These Barriers Enhance Safety in Construction and Industrial Sites?

In construction and industrial sites, portable barriers serve to isolate excavation edges, cordon off machinery under maintenance, and separate pedestrian routes from vehicle traffic. The reason they work is twofold: they provide a physical deterrent that reduces unauthorised entry and a clear visual boundary that improves situational awareness for both operators and pedestrians. For rugged environments, features such as weighted or concrete-fillable bases, corrosion-resistant posts and reinforced belt housings are critical to maintain stability in wind or uneven ground. Implementing barriers as part of a documented method statement and as temporary controls during high-risk operations reduces exposure to vehicle strike, falls and unexpected machine start-ups.

These operational uses naturally segue into how barriers support compliance with UK regulations, which is essential for audit readiness and risk management.

What Role Do Retractable Barriers Play in Retail and Event Crowd Control?

In retail and events, retractable barriers manage queues, direct footfall and create temporary closures while maintaining an orderly environment that protects staff and visitors. They improve safety by preventing overcrowding at chokepoints, guiding customers around hazards and enabling staff to reconp spaces quickly during peak periods or for emergency egress routes. Aesthetic options—coloured or branded belts, polished posts—allow establishments to meet safety needs without compromising customer experience. Rapid reconfiguration also supports operational resilience, allowing event teams to adapt circulation plans in response to changing crowd dynamics and emergency plans.

How Do Portable Retractable Safety Barriers Comply with UK Safety Regulations?

Portable retractable safety barriers support compliance by acting as documented control measures within risk assessments and safe systems of work, aligning with the practical expectations of UK guidance such as PAS 13 and PUWER when used appropriately. Their role is not to replace formal engineering controls but to provide temporary, visible controls that reduce risk exposure while permanent measures are arranged. Employers must demonstrate that barrier selection, deployment and inspection are recorded as part of the overall safety management plan so that temporary controls are auditable and effective. When barriers are specified with suitable attributes—visibility, stability and maintainability—they form an acceptable element of a layered risk control strategy.

What Are the Key UK Standards Like PAS 13 and PUWER 1998?

PAS 13 provides specific guidance relevant to barrier performance and testing where temporary physical controls are concerned, while PUWER 1998 obliges employers to ensure equipment used at work is safe, suitable and maintained. In practice this means selecting barriers that are fit for purpose, training staff in correct deployment and keeping inspection records that show ongoing suitability. Employers should treat portable barriers as part of the control hierarchy: document the hazard, select an appropriate barrier type, train users and record inspections to show due diligence. These steps create traceable compliance evidence that temporary controls were considered and maintained.

How Do Barriers Help Businesses Meet Workplace Safety Requirements?

Barriers help businesses meet workplace safety requirements by providing a visible, controllable measure that reduces access to hazards and supports safety procedures in real time. Key practical actions include logging deployment in the site safety register, performing routine inspections for belt wear and base integrity, and scheduling maintenance or replacement where components degrade. A simple audit checklist for barrier use should cover selection rationale, deployment time, inspection dates and any repairs—this documentation demonstrates that temporary controls are managed proactively. Using portable barriers in this way reduces exposure, supports incident prevention and provides clear records for regulators and auditors.

What Factors Should You Consider When Choosing Portable Retractable Safety Barriers?

Choosing the right portable retractable safety barrier requires assessing material, visibility, base stability, portability and lifecycle cost against the intended application and regulatory needs. Material choices affect weight, corrosion resistance and maintenance; base design determines surface suitability and wind stability; visibility features such as high-contrast belts or reflective strips influence recognisability in different lighting. Consider how often barriers will be deployed, whether belts need branding or colour coding, and whether replacement parts are readily available to keep maintenance simple. The following table compares common materials to help prioritise attributes for different use-cases.

Material comparison for barrier selection:

|

Material |

Durability |

Weight / Portability |

Typical Use-case |

|---|---|---|---|

|

Steel |

High, robust |

Heavier, less portable |

Permanent temporary zones, outdoor use |

|

Aluminium |

Moderate-high, corrosion resistant |

Lighter, portable |

Indoor/outdoor mixed use |

|

Plastic / Polymer |

Moderate, weather-resistant |

Very light, highly portable |

Short-term interior events and retail |

This table shows that aluminium often balances durability and portability, steel favours rugged sites and plastic suits light, frequent moves. As a practical next step, use the checklist below to finalise selection and procurement.

Checklist for choosing and maintaining barriers:

1. Match material to environment: prioritise corrosion resistance for outdoor/industrial sites.

2. Verify base stability: choose weighted or concrete-fillable bases for uneven ground or high wind.

3. Assess visibility options: use high-contrast belts and reflective strips where lighting is poor.

4. Consider maintenance: ensure belts and retractors are replaceable and inspection-friendly.

5. Plan storage and transport: confirm folded dimensions and case options for rapid deployment.

This checklist helps translate selection criteria into concrete purchasing decisions; to review product options that meet these attributes, explore suppliers who list portable retractable safety barriers, retractable belt barriers and rope barriers and highlight durability, customisation and same-day dispatch as purchasing advantages.

How Do Material, Visibility, and Base Design Affect Barrier Performance?

Material determines how a barrier copes with abrasion, impact and weather; steel offers the highest toughness while aluminium balances strength with lower weight, and polymer components enhance portability for indoor use. Visibility features—belt colour, contrast, reflective trims—affect how quickly people detect a hazard from a distance and therefore influence reaction time and compliance with local lighting conditions. Base design is the final determinant of whether a barrier remains upright under accidental impact or wind; options include weighted flat bases, rubber-socket bases and concrete-fillable units for extreme stability. Choosing the right combination ensures a barrier performs consistently within the expected operational environment.

Why Is Durability and Cost-Effectiveness Important for Long-Term Use?

Durability and cost-effectiveness matter because barriers are operational tools: frequent deployments, inspections and repairs all contribute to total cost of ownership. A more durable unit may cost more upfront but reduces replacement and downtime costs, whereas cheaper options can incur higher lifecycle expenses if belts and retractors fail. A simple way to assess value is to estimate cost per deployment over an expected service life and factor in maintenance time. Regular inspection—quarterly in high-use sites, biannually in low-use—extends life and ensures the barriers continue to support safe operations without surprise expenditure.